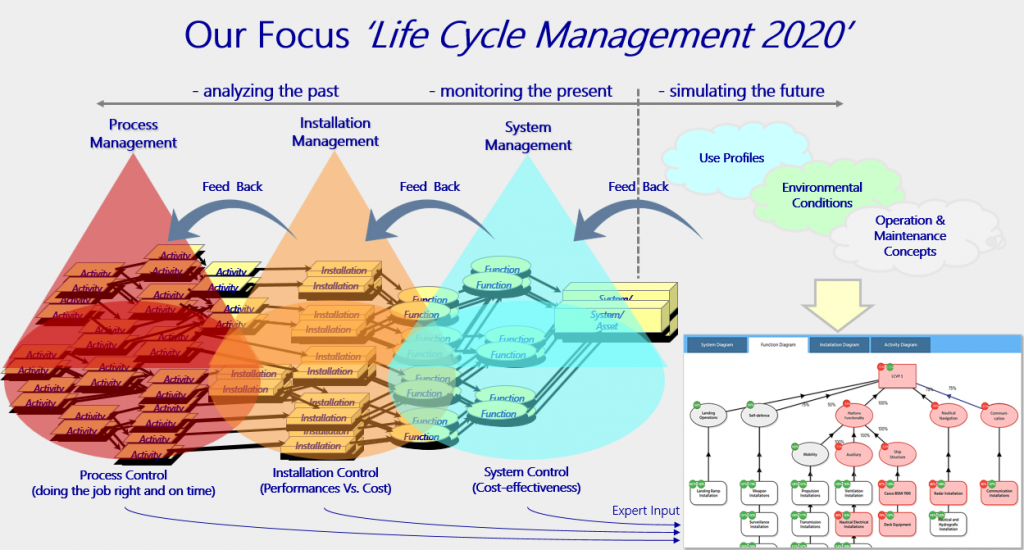

Life Cycle Management

In this module, LCM is presented as a method that enables organizations to make decisions based on ‘System Cost-Effectiveness’. The required ‘system output’ is presented in such a way that it is also possible to start working on the basis of performance contracts, whereby the ‘customer’ (owner / operator) can then make choices based on the (production) output to be realized. both the short and long term.

With LCM the following is pursued:

- influencing the design and realization of an asset in order to minimize the lifetime costs, with regard to RAMS SHEEP (Reliability, Availability, Maintainability, Safety, Security, Health, Environment, Economics and Politics);

- designing an optimal arrangement of the logistical support during the exploitation phase;

- being able to determine the necessary maintenance activities per maintenance level;

- being able, in conjunction, to define the necessary maintenance needs for the maintenance phase, such as; spare parts, tools, measuring and testing equipment, technical documentation, facilities, maintenance software, training and personnel;

- being able to actually provide logistical support at the lowest possible total costs;

- the timely detection of obsolescence / technical obsolescence of system parts and / or components, in order to prevent related problems;

on the basis of so-called ‘real options’, elaborate alternatives to support decision-making by (higher) management.